After three successful workshops in the U.S. and Germany—we’re thrilled to announce additional dates!

XO Dynamic Learning isn’t a typical problem-solving methodology. As co-founders of the method and workshop leaders, John Allen and David Hartshorne will tell you, “Forget about solving problems”… at least not until you’ve first developed a deep understanding of how your manufacturing system actually behaves. In a world obsessed with quick fixes, this foundational shift in focus is both revolutionary and essential. And now, we could be bringing this powerful method to a location near you!

Here’s what workshop attendees have to say:

Amazing!!! Training perfectly aligned with my needs / expectations to reinforce technical skills to be more effective & efficient in diagnosing and solving technical problems.

My expectations were high and it just blew my mind!

This workshop was an incredibly enriching and invaluable experience. The mix of real-life stories, humorous remarks, and simple principles made it easy to remember the content.

Whether you’re an engineer, operations leader, or continuous improvement champion, these immersive two-day sessions will equip you with the tools and mindset needed to master system behavior before jumping into solutions.

XO Dynamic Learning 2025 – Past Workshops:

March 25-26 in Livonia, Michigan

April 23-24 in Livonia, Michigan

May 20-21 in Munich, Germany

July 22-23 in Queretaro, Mexico

August 13-14 in Michigan, USA

November 5-6 in Bangkok, Thailand

November 12-13 in Munich, Germany

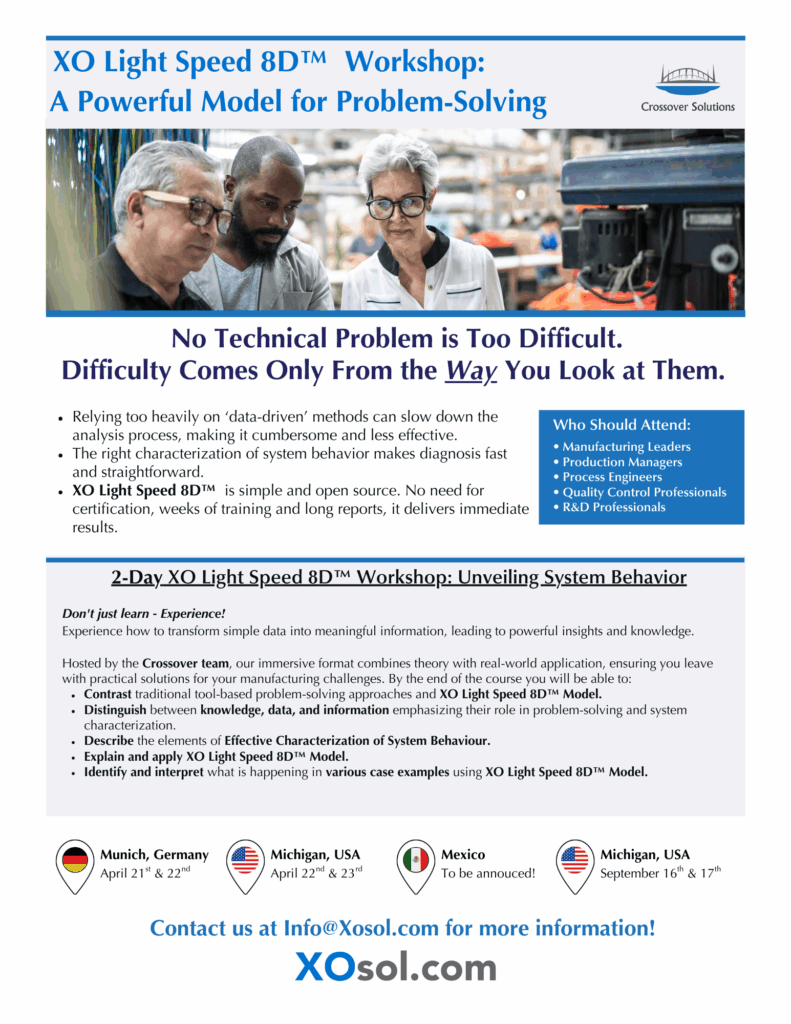

XO Dynamic Learning 2026 – New Workshops Scheduled:

April 21-22 in Munich, Germany

April 22-23 in Livonia, Michigan

Early 2026 in Monterrey, Mexico

September 16-17 in Livonia, Michigan

Another EU workshop to be announced!

Register below for our North American workshops or contact us at info@xosol.com for our international workshops.

Secure Your Spot Today!

Click here to download our Dynamic Learning Workshop Flyer.

What is the XO Dynamic Learning Method?

XO Dynamic Learning, as outlined in Simple Strategies by John Allen and Diagnosing Performance and Reliability by David Hartshorne, offers a refreshing approach to problem-solving in manufacturing

environments. Traditional methodologies like DMAIC, 8D, and 7-Step typically begin by defining the problem and rely on extensive data analysis, large teams, and prolonged processes. In contrast, XO Dynamic Learning proposes a streamlined, foundational step that prioritizes understanding system behavior before diving into complex problem-solving frameworks. This method, rooted in over 30 years of experience each from both authors, challenges the overcomplication that has plagued many projects, advocating for a return to first principles thinking.

The process begins with a small group – typically three or fewer engineers, such as a Manufacturing Engineer (ME), Product Engineer (PE), or Quality Engineer (QE) – collaborating to characterize the system. Rather than jumping to problem definition, they focus on creating a simple, hand-drawn diagram of the process. Pencil and paper are preferred, allowing for easy corrections as the team maps out key elements, whether it’s a single station or a continuous flow. This diagram might include machinery like drills or pumps, assembly nests, or substrates being altered, coated, or assembled. It doesn’t matter if the machine or device is a process or a product – function, and its characterization is key. For a process, there is very often additional information available from the “footprint” it leaves on its product. More information, not more data, is the key to understanding what is happening and building knowledge. The goal is to establish a shared, straightforward understanding of the system without the burden of excessive data or meetings.

Once the diagram is sketched, the team builds a basic model comprising four elements: Supply, Transmit/Convert function, Load, and Source/Loss. At each stage, the process is analyzed through the lens of energy, described in terms of “effort” (forces like force, torque, pressure, or voltage) and “flow” (movements like linear displacement, radial displacement, flow, or current). After agreeing on this model, the group walks through a single cycle of the process in detail. The most important source of information, typically missing in most analytical approaches, is what happens in this single cycle. Notably, this exercise requires no data collection, no action lists, and no formal meetings – just a focused effort to align on the system’s key behaviors.

Allen and Hartshorne argue that this step is the critical, often-missing foundation for effective problem-solving. By ensuring a small team understands the process in a standardized way, XO Dynamic Learning eliminates miscommunication and misaligned assumptions that frequently derail larger, data-heavy methodologies. From an organizational and leadership perspective, this approach makes intuitive sense: how can a team solve a problem if they don’t first agree on what the process entails? When engineers – say, a PE, ME, and QE – share a common language and mental model, they can tackle issues more efficiently, speaking the same “process language” as they collaborate.

The potential benefits are significant. XO Dynamic Learning could enhance productivity in design initiatives and manufacturing troubleshooting by reducing the need for drawn-out analyses and bloated teams. It empowers a lean group to lay the groundwork for success, potentially transforming how organizations approach challenges. Drawing from decades of practical insight, Allen and Hartshorne present XO Dynamic Learning as a groundbreaking yet logical return to simplicity, proving that understanding the system is the true first step to solving any problem.

Hosted by our Global Leaders

Crossover Solutions has a global footprint with team members located in: United States, Canada, Mexico, Germany, UK, Turkey, China, Thailand, South Korea and Saudi Arabia to expertly deal with your risk situations regardless of geography.

About Crossover Solutions:

Crossover Solutions is a leading manufacturing consultancy firm specializing in providing comprehensive manufacturing and management consulting services to clients across the globe. We deliver innovative solutions that enhance operational efficiency, drive growth, and optimize performance. Our team of leaders and experts combines deep industry knowledge with strategic thinking to empower organizations to thrive in today’s competitive landscape.